Engineering Plastics Halesowen

The One Stop Metal and Plastic Shop

Engineering Plastics- Used in Mass Production

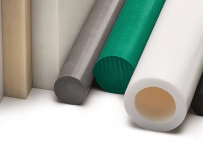

Engineered plastics are crafted with a focus on strength, toughness, and durability. Ideal for extended use in structural applications, these materials excel across a broad temperature spectrum, endure mechanical stress, and thrive in challenging chemical and physical environments. Plastic can often replace the use of metals and ceramics in many industries as a reliable, adaptable and cheaper solution for projects and moulds. For engineering plastics Halesowen, Jade Metals can help you find the type you need.

Our product range includes: Natural Acetal, Natural Nylon, Polyether Ether Ketone (PEEK), Tufnol,

Processing Methods

At Jade Metals we have a range of engineering plastics Halesowen, that are suitable for engineering industries and effectively replace the need for metals. Here are some of the processes of using our engineering plastics.

Applied in large-scale production, injection moulding is a technique employed for the production of finished products that are ready for use. The process involves melting plastic with an extruder, plasticising it, and then injecting it under pressure into an injection moulding tool. This tool, equipped with diverse cavities and shapes, dictates the final form and surface texture of the produced component.

Extrusion is a controlled process that utilizes temperature and pressure. In this method, the material undergoes heating within an extrusion barrel, progressing through zones of escalating heat, and is subsequently propelled through a uniquely designed die under pressure. The outcome is frequently a semi-finished mould, which can be subsequently refined to meet precise specifications. This refinement may involve producing stock bars, tubes, or plates in various dimensions and colours.

Compounding is a procedure in which the plastic's raw material is fused with fillers or additives. The resulting mixture is then extruded into slender strands and subsequently sliced into granulated form. This technique enables the customisation of the particular plastic to meet specific specifications or design criteria, such as improving frictional capabilities or augmenting electrical conductivity.

Machining stands out as the predominant, swiftest, and most economical approach to achieving a finalised product. This method is particularly adept at crafting precision-engineered components from engineering and high-temperature plastics. Utilising CNC milling machines, lathes, and saws equipped with specialized tools, machining plays a pivotal role in shaping and designing the desired product form. It serves as the crucial shaping stage following the creation of the stock shape or injection-moulded part.

Why Choose Jade Metals?

- Commitment to Quality- Jade Metals offers engineering plastics Halesowen that demonstrate superior performance in diverse applications. Their materials undergo rigorous testing to ensure they meet stringent industry standards, providing reliability and durability in the most demanding conditions.

- Comprehensive Range- Jade Metals boasts a comprehensive range of engineering plastics that can be tailored to specific project requirements, offering versatility in design and application.

- Dedication- Our company's dedication to innovation and continuous improvement ensures that our products remain at the forefront of technological advancements, making us an ideal choice for those seeking top-tier engineering plastics backed by a reputation for excellence.

Don't hesitate to contact the team here at Jade Metals, we can direct you toward the products you need and have them delivered in no time to you! If you have any queries about the product that's best for your projects, we can help you find what you need. Whether you need engineering plastics Halesowen or you're looking for our other products , see here.