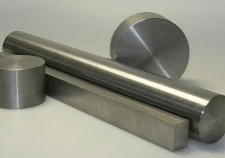

O1 Tool Steel

Air-hardening steels, high-carbon, high-chromium steels, and oil-hardening steels are the three subgroups of high carbon steels that are used in cold-work tool fabrication. Oil-hardening cold-work steels, which include the O1, O2, O6, and O7 kinds, are also referred to as group O steels.

The comparatively cheap Type O1 oil-hardening cold-work steel is composed of tungsten, manganese, and chromium. The O1 type is described in full in the datasheet that follows.

Chemical Composition

The following table shows the chemical composition of O1 tools steels.

| Element | Content (%) |

| C | 0.85-1.00 |

| Mn | 1.00-1.40 |

| Si | 0.50 |

| Cr | 0.40-0.60 |

| Ni | 0.30 |

| W | 0.40-0.60 |

| V | 0.30 |

| Cu | 0.25 |

| P | 0.03 |

| S | 0.03 |

Physical Properties

The physical properties of O1 tool steels are outlined in the following table.

| Properties | Metric | Imperial |

| Density (hardened to 62 HRC) | 7.81 g/cm3 | 0.282 lb/in3 |

| Density (@399°C/ 750°F, hardened to 62 HRC) | 7.70 g/cm3 | 0.278 lb/in3 |

| Density (@191°C/ 375°F, hardened to 62 HRC) | 7.75 g/cm3 | 0.280 lb/in3 |

| Melting point | 1421°C | 2590°F |

Mechanical Properties

The mechanical properties of O1 steels are tabulated below.

| Properties | Metric | Imperial |

| Hardness, Brinell (soft annealed -delivery condition) | 190 | 190 |

| Hardness, Rockwell C (tempering temp 300-1200°F) | 34.0-64.0 | 34.0-64.0 |

| Elastic modulus (hardened to 62 HRC) | 193 GPa | 28000 ksi |

| Elastic modulus (@399°C/750°F, hardened to 62 HRC ) | 172 GPa | 25000 ksi |

| Elastic modulus (@191°C/375°F, hardened to 62 HRC) | 186 GPa | 27000 ksi |

| Compressive yield strength (0.2%, hardened to 50 HRC) | 1350 MPa | 196000 psi |

| Compressive yield strength (0.2%, hardened to 55 HRC) | 1800 MPa | 261000 psi |

| Compressive yield strength (0.2%, hardened to 60 HRC) | 2150 MPa | 312000 psi |

| Compressive yield strength (0.2%, hardened to 62 HRC) | 2200 MPa | 319000 psi |

Thermal Properties

The table below shows the thermal properties of O1 tool steels.

| Properties | Conditions | ||

| T (°C) | Treatment | ||

| Thermal expansion | 10.6 x 10-6/ºC | 20-260 | - |